The machines with built-in control software often rely on a tiny keypad, or pendant, (a hand-held control pad) for input, allowing you to get much closer to the bit as you position it. While using a regular computer grants you a bigger screen to control the action, it can be cumbersome as you make the final tweaks to the bit’s position. Control software doesn’t require a lot of computing power, and having a shop laptop keeps your good computer away from the dust. If your machine requires a separate computer, consider investing in an inexpensive or used laptop for dedicated CNC use. Some CNC machine manufacturers require a separate computer to run the software, while others have it built right into their machines. This program also tells it what file you want to run.

The first piece of software to navigate operates your machine, allowing you to position the router’s bit so that it starts cutting in the right place.

Once you learn the quirks of your new shop assistant, you’ll be creating great projects in all kinds of exciting and time-saving ways. While there are some proprietary differences in the machines from individual manufacturers, they all work about the same way.

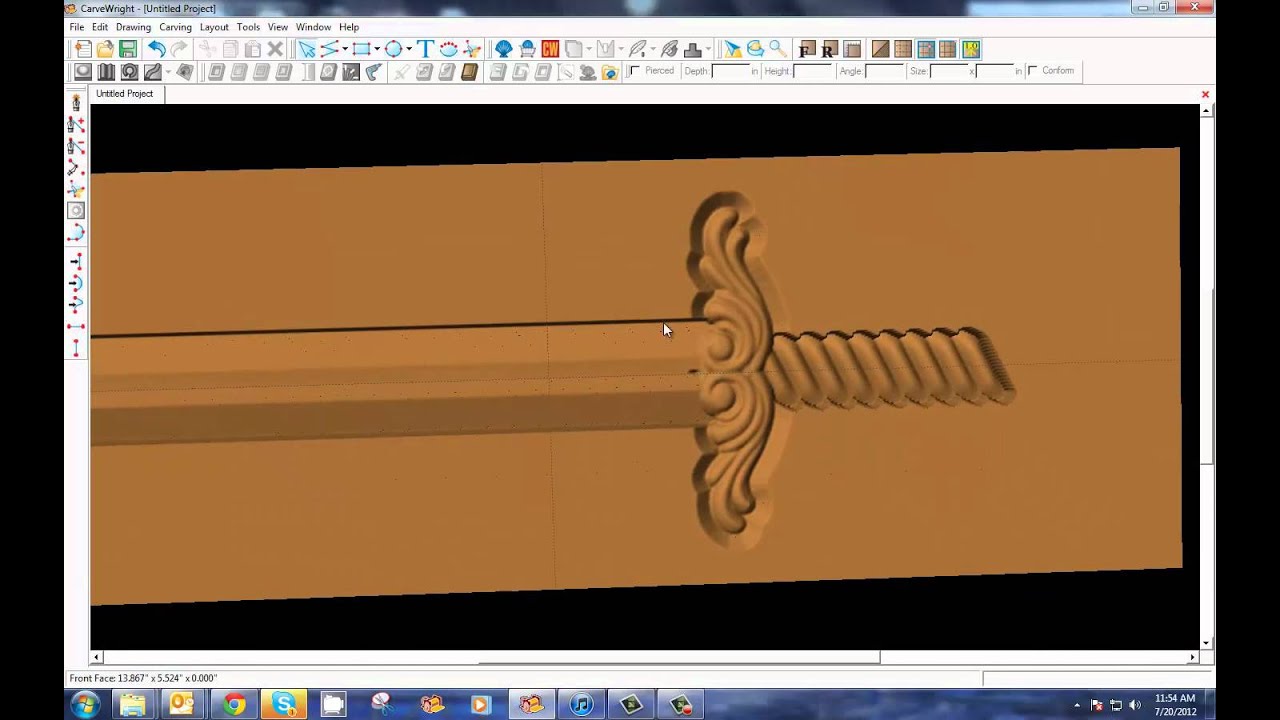

CARVEWRIGHT DEMO SERIES

With one program, you design tool paths (a series of coordinate locations that the router will follow) and the other communicates those paths to the router. The computer part usually involves two software programs responsible for making the router move. In woodworking, the vast majority of CNC machines available are routers with several components that make them work, including the machines themselves and the computer(s) that drive them. The learning curve is not as steep as you might imagine, and plenty of online resources and forums are available to help when you have questions. Once you get the hang of using it, you’ll be amazed at what it can do. That’s not to say these machines are cheap, but for the investment of two to three thousand bucks, you can employ a quite capable workshop assistant that can do a lot for you, including creating signs, shaping templates, making parts, cutting joints, and even carving forms. A newbie’s guide to your electronic shop helperĬNC (Computer Numeric Control) technology is becoming more and more affordable.

0 kommentar(er)

0 kommentar(er)